Spray towers have become essential in various industries, from water treatment to air pollution control. According to a report by the Environmental Protection Agency, these systems significantly enhance gas-liquid mass transfer efficiency, improving overall process performance. John Smith, a recognized expert in spray tower technology, notes, "The strategic use of spray towers can revolutionize industrial operations."

One of the notable benefits of spray towers is their ability to reduce operational costs. Studies indicate that industries using spray towers can achieve up to a 30% reduction in energy consumption. However, not all systems are optimized, leading to inefficiencies. It's crucial for manufacturers to continuously evaluate their spray tower designs.

Furthermore, spray towers contribute to environmental sustainability. They help industries comply with increasingly strict emissions regulations. Despite their advantages, integrating new technologies like spray towers can be challenging. Companies must navigate installation complexities and maintenance requirements. Balancing benefits with operational hurdles is vital for maximizing spray tower effectiveness.

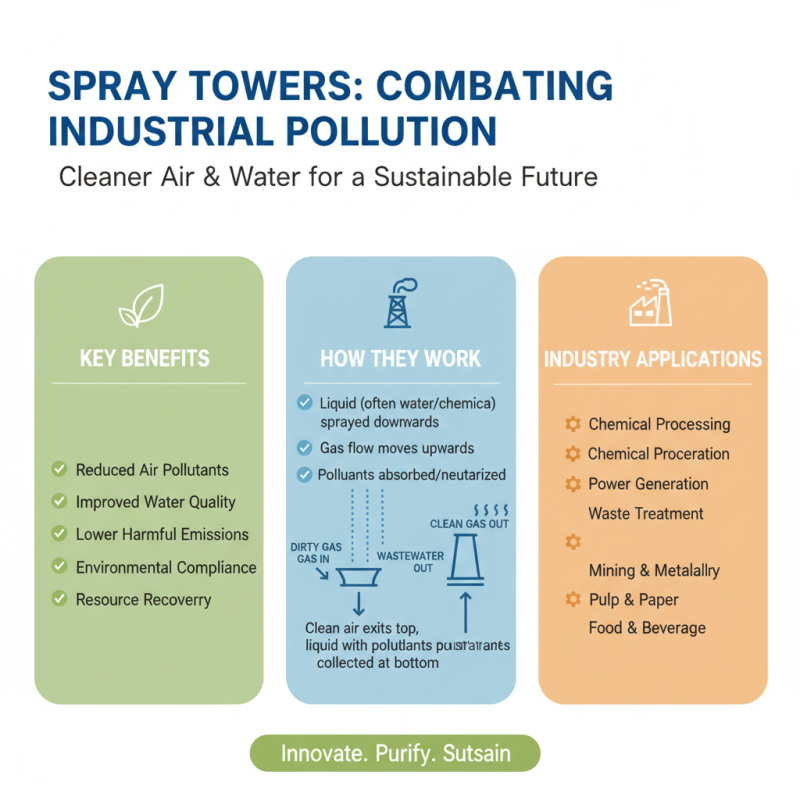

Spray towers play a crucial role in various industrial applications. They are designed to facilitate mass transfer between a gas and a liquid. This design helps in removing contaminants from gases, enhancing air quality in many industries. Spray towers also assist in cooling processes. They create fine droplets that improve contact between the liquid and gas phases.

When thinking about implementing spray towers, consider their application. For instance, they are widely used in power plants and chemical industries. In these settings, they can effectively capture pollutants like sulfur dioxide. The efficiency of spray towers often hinges on nozzle design. Proper nozzle selection can lead to better droplet size and distribution.

Tips: Regular maintenance is vital. Check nozzles for blockages. Blocked nozzles can reduce efficiency significantly. It’s also essential to monitor liquid flow rates. Too low or too high can hinder performance.

Additionally, explore the placement of spray towers. Ensure they are set up where they can operate most effectively. There might be room for improvement in your existing systems. Reflecting on current operational practices can lead to better outcomes.

Spray towers play a crucial role in enhancing air quality control in various industrial settings. These systems utilize a unique process to remove pollutants from the air. By atomizing water into fine droplets, they capture harmful particles and gases effectively. The water droplets coalesce with contaminants, making them easier to filter out. This mechanism is particularly beneficial in environments with high levels of dust and harmful emissions.

One notable advantage of spray towers is their ability to greatly reduce respiratory hazards. Workers in industries face exposure to harmful air pollutants daily. Spray towers help mitigate these risks by maintaining cleaner air. Their design allows for efficient water use, minimizing waste. However, regular maintenance is necessary to ensure optimal performance. Neglecting this can lead to reduced efficiency and potential hazards. While spray towers offer substantial benefits, continuous monitoring is essential for long-term success. Proper adjustments may be needed to adapt to changing environmental conditions.

Spray towers are revolutionizing cooling processes in various industries. They efficiently disperse water droplets into the airstream. This creates a larger surface area for heat transfer. As hot air passes through, it cools down quickly. This method can reduce the temperature significantly. However, there can be challenges like scaling if not maintained properly.

In addition to cooling, spray towers enhance air quality. They can remove pollutants and improve overall efficiency. Yet, not all installations are perfect. Some systems may require regular adjustments. If the water quality is poor, it could lead to operational issues. Monitoring water composition is essential for optimal performance.

Spray towers also have an added benefit of being cost-effective. They use less energy compared to traditional cooling systems. This can lead to lower operational costs in the long run. However, strict adherence to maintenance schedules is necessary. A neglected system could become less efficient over time. Consistent evaluation can ensure the towers perform at their best.

| Benefit | Description | Impact |

|---|---|---|

| Energy Efficiency | Significantly reduces energy consumption in cooling processes. | Lower operational costs. |

| Improved Cooling Capacity | Enhances the cooling capacity compared to traditional systems. | Increased efficiency in temperature control. |

| Reduced Water Usage | Minimizes water waste through effective circulation methods. | Cost savings and sustainability improvements. |

| Easy Maintenance | Requires minimal upkeep to function effectively. | Saves time and labor costs. |

| Versatile Application | Applicable in various industries including chemical, food processing, and more. | Flexibility in industrial use. |

| Environmental Compliance | Helps meet environmental regulations through efficient operations. | Enhanced corporate responsibility. |

| Enhanced Worker Safety | Reduces the risk of overheating and associated injuries. | Improved workplace safety standards. |

| Lower Operating Costs | Overall reduction in energy and maintenance costs. | Increased profitability. |

| Increase Process Efficiency | Optimizes the cooling process for improved operation times. | Higher production rates. |

| Cost-effective Installation | Installation is generally less complex and costly. | Faster deployment and return on investment. |

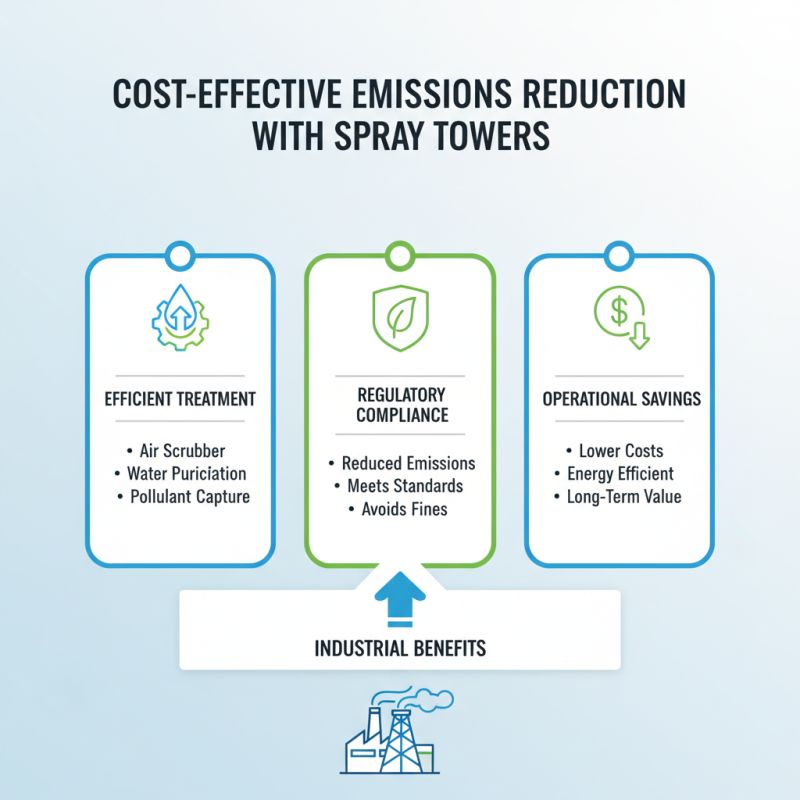

Implementing spray towers in industrial settings can be cost-effective. These systems offer efficient air and water treatment. They reduce harmful emissions while maintaining regulatory compliance. This can lead to lower fines and reduced operational costs in the long run.

Maintenance costs are also a crucial factor. Spray towers generally require less frequent servicing. This decreases downtime and boosts productivity. However, initial installation can be expensive. Companies need to assess their budgets carefully. Not all facilities may find it feasible at first.

Energy consumption is another consideration. Spray towers focus on optimizing resource use. They often consume less energy compared to other systems. Yet, this advantage can vary by operation type. Regular monitoring is essential to ensure efficiency remains high. Industries must continually evaluate their processes for maximum benefit.

Spray towers are gaining popularity in various industries. They offer significant benefits for reducing environmental impact. These towers can effectively capture pollutants and minimize harmful emissions. Air and water quality often suffer from industrial operations. Spray towers aim to address these issues with innovative designs.

One of the primary advantages is the reduction of particulate matter. Spray towers use mist to absorb and neutralize pollutants. The captured particles then settle, preventing them from entering the atmosphere. Industries can achieve cleaner emissions by using spray towers. However, not all designs are equally effective. Some may struggle with specific pollutants, leading to incomplete filtration.

Water usage is another concern. While spray towers require water for operation, careful management can minimize waste. Adequate maintenance is crucial to prevent leaks and inefficiencies. In some cases, water treatment may be needed. Therefore, operators must continually assess efficiency and environmental impact. The balance between effective pollution control and resource management remains a complex challenge.