In the world of liquid coating applications, efficiency and precision are paramount. Spray Tower technology has emerged as a frontrunner in delivering high-quality finishes. These machines utilize a unique design to ensure an even distribution of liquid coatings. The advantages of Spray Towers extend beyond mere aesthetics; they enhance performance and reduce wastage.

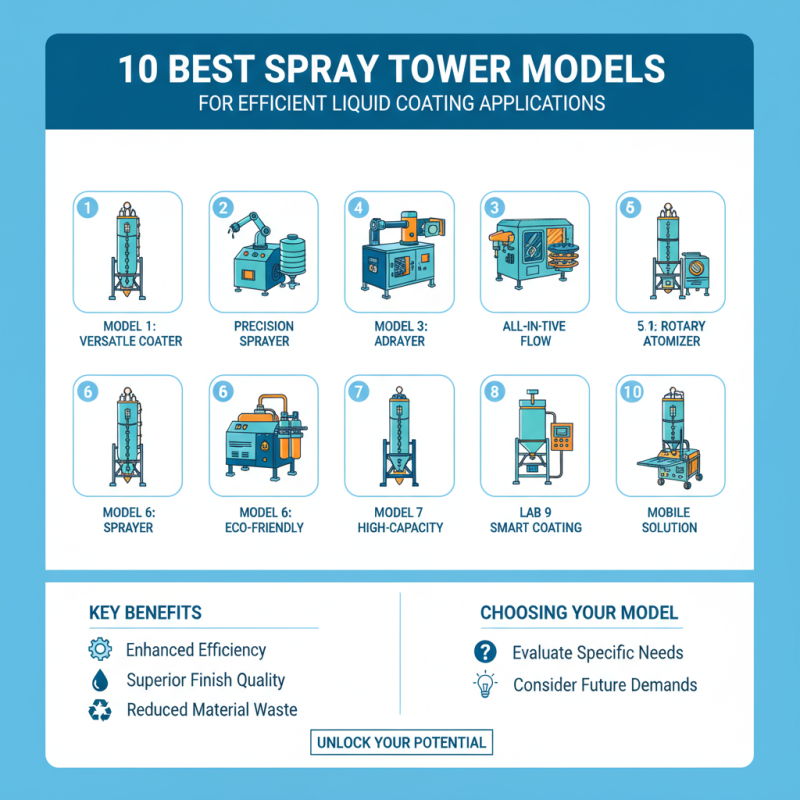

Understanding the various models available can be challenging. Some machines excel in versatility, while others focus on specific applications. As industries evolve, so do the demands for Spray Towers. Efficiency is key, but are we fully utilizing their potential? It's essential to evaluate what each model offers and how it aligns with your specific needs. Some users may overlook crucial features that could enhance their operations.

Choosing the right Spray Tower model is not always straightforward. However, it can significantly impact productivity and quality. A well-informed decision can drive better results, but mistakes can lead to setbacks. Reflecting on these factors will help you navigate the complexities of your choices.

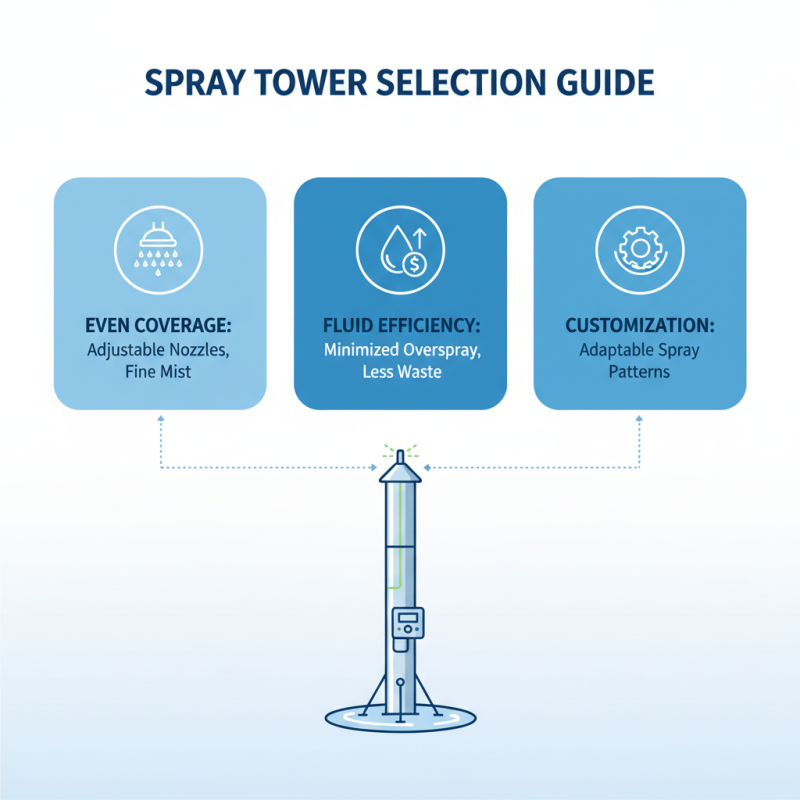

Spray tower technology offers advanced solutions for liquid coating applications across various industries. These systems utilize a series of nozzles that create a fine mist, ensuring even coverage of surfaces. This technology is particularly useful in sectors like automotive, aerospace, and manufacturing, where precision is vital. Spray towers can handle various liquids, including paints, adhesives, and coatings, enhancing efficiency.

The design of spray towers often includes adjustable parameters. This allows for customization based on the specific requirements of each coating process. However, achieving the desired coating thickness can be challenging. Factors such as humidity, temperature, and fluid viscosity come into play. Operators must closely monitor these variables to ensure optimal results.

There is always room for improvement in process stability and reproducibility. This complexity might lead to inconsistent outcomes, requiring ongoing adjustments and testing. Proper training for staff is essential to minimize these issues, as human error can significantly affect results.

When selecting a spray tower model, several key features are essential. The spray mechanism should ensure even coverage. Look for adjustable nozzles, as they allow for customized spray patterns. A model with a fine mist option is beneficial for delicate applications. Efficiency in fluid consumption is also a highlight. Some towers minimize overspray, resulting in less waste.

Consider the material of the tower itself. Robust materials are vital for longevity. They should withstand various chemicals without degrading. The design should facilitate easy cleaning to maintain optimal performance. Operators often overlook maintenance ease, which can lead to inefficiencies.

Moreover, examine the height and size of the tower. A taller spray tower might provide better coverage for larger projects. However, space constraints must also be considered. If the footprint is too large, it may hinder workflow. Assessing these features carefully will enhance your liquid coating operations.

When it comes to achieving liquid coating efficiency, selecting the right spray tower model is essential. Recent industry reports indicate that the application efficiency of liquid coatings can vary significantly based on the technology used. For instance, modern spray towers can achieve up to 90% transfer efficiency, optimizing material usage and reducing waste. However, not all models live up to these claims, making careful evaluation crucial.

A study by the Coating Industry Association highlights that incorrect nozzle selection can lead to over-spray, wasting valuable materials. This common oversight contributes to increased operational costs in many facilities. Moreover, it’s worth noting that while some advanced models promise high efficiency, they may also come with complex maintenance requirements. This trade-off can detract from overall productivity.

User feedback often reveals dissatisfaction with certain features in popular models. Issues like inconsistent coating thickness and a tendency for clogging must be addressed. Choosing a model provides options that excel in specific applications. Balancing efficiency and practicality remains a challenge for many operators. The quest for the best spray tower model is ongoing, reflecting both advancements and the persistent need for improvement in the industry.

When selecting spray towers for liquid coating applications, understanding performance metrics is crucial. Different models offer varying efficiency levels, which impact the final results. Some units may excel in speed, applying coatings quickly, but struggle with uniformity. Others provide a smooth finish but may have slower application rates.

Evaluating the coverage area is essential. Some models may cover large surfaces, yet they might waste material. In contrast, certain compact designs focus on precision, trimming excess wastage but limiting the application scale. Each model presents trade-offs, highlighting the need for careful consideration based on specific project requirements.

It's also important to reflect on maintenance needs and ease of cleaning. Some designs might be prone to clogs, necessitating more upkeep. Users often overlook these aspects, which can affect long-term efficiency. Balancing performance with maintenance can be a daunting task, but it's vital for achieving consistent results in liquid coating.

Spray towers are vital for efficient liquid coating applications. To ensure optimal performance, regular maintenance is essential. Studies suggest that proper upkeep can extend their lifespan by up to 30%. Ignoring maintenance can lead to issues such as uneven coating and increased downtime.

Regular inspections are crucial. Check for wear and tear on nozzles regularly. Nozzle blockages can reduce spray efficiency drastically, sometimes by over 25%. Cleaning these parts helps maintain a consistent spray pattern. It is also important to monitor fluid levels continuously. Low levels can cause damage to the pump, leading to costly repairs.

Record maintenance activities. Documentation helps track service frequency and identifies patterns in breakdowns. Consistent maintenance prevents unexpected failures. Inadequate maintenance practices circulate old data about performance, leading to misguided investments. As experts highlight, silent problems can evolve into major failures. Address small issues quickly to maintain operational efficiency.