In the realm of testing and measurement, selecting the right equipment is crucial for ensuring accurate results and optimal performance. The All Steel Test Bench stands out as a versatile and durable option for professionals across various industries. Dr. Emily Hart, a leading expert in mechanical engineering, emphasizes, "A robust testing environment begins with the right bench; the All Steel Test Bench provides the stability and reliability required for precise measurements."

As technology advances, the demand for high-quality testing solutions increases. The All Steel Test Bench caters to a wide array of applications, making it essential for engineers and technicians to understand its features and benefits. By evaluating specific needs, such as load capacity, size, and functionality, users can make informed decisions that enhance their workflow and productivity.

Ultimately, investing in an All Steel Test Bench not only reflects a commitment to quality but also signifies the importance of selecting equipment that aligns with one's professional requirements. It is vital to consider various factors that contribute to the effective use and longevity of the bench to ensure that it meets all operational demands.

A test bench is an essential tool across a range of applications, serving as a controlled environment for evaluating the performance and reliability of various products and systems. Whether in electronics, automotive, or manufacturing, a well-constructed test bench provides an efficient setup for conducting experiments, troubleshooting, and ensuring quality assurance. Its importance lies not only in facilitating detailed analysis but also in allowing engineers to simulate real-world conditions, which is crucial for understanding how a product will perform in real-time scenarios.

In electronics, for instance, a test bench enables the assessment of circuit functionality and efficiency, allowing engineers to identify potential flaws and optimize designs before mass production. Similarly, in the automotive industry, test benches are invaluable for testing components like engines and brake systems, ensuring they meet safety and performance standards. The versatility of test benches extends to various industries, emphasizing their role in improving product development cycles, enhancing safety measures, and ultimately leading to higher customer satisfaction through reliable products.

When selecting the best all steel test bench, the first step is to deeply understand your specific testing requirements and objectives. Consider the types of materials and products you will be testing, as these factors will dictate the size and strength of the test bench. For instance, if you plan to work with heavy-duty components, your bench will need to have a robust construction that can withstand high loads and provide accurate results. Additionally, you should evaluate the range of tests you intend to conduct, whether they are mechanical, electrical, or hydraulic in nature, as this will influence the configuration and features of the bench you need.

Furthermore, it is crucial to assess your desired accuracy and reproducibility levels for the testing processes. High precision may demand additional features such as integrated measurement tools or advanced clamping mechanisms, which can enhance the reliability of your results. Also, consider any safety standards applicable to your industry, as ensuring compliance will help in selecting a bench that not only meets your technical needs but also provides a safe working environment. By taking the time to define your requirements clearly, you position yourself to make a more informed decision when choosing the optimal all steel test bench for your specific applications.

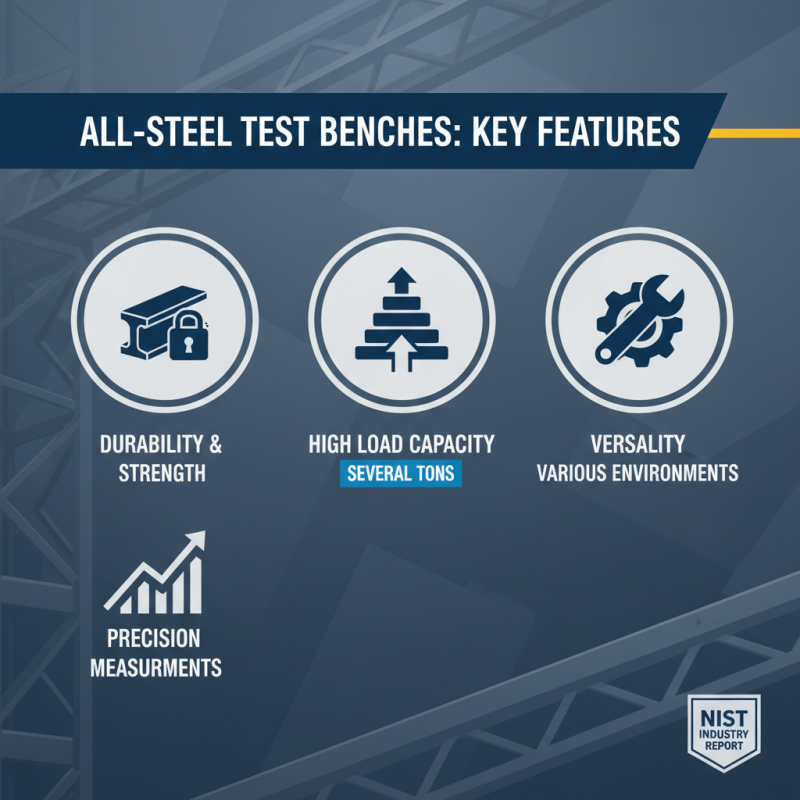

When evaluating key features of all steel test benches, it's essential to consider the materials used in construction, load capacity, and versatility. All steel construction ensures durability and resistance to deformation, making it suitable for various testing environments. According to a recent industry report by the National Institute of Standards and Technology, high-strength steel test benches can support up to several tons of equipment, providing a stable platform for precision measurements.

Another critical factor is the design and layout of the test bench. A well-designed bench can improve efficiency and ease of use, facilitating a smoother workflow. Features such as adjustable height and modular designs can enhance ergonomics and usability, especially in busy testing labs. Research from the Laboratory Equipment Manufacturers Association highlights that benches with adjustable features can improve user satisfaction by up to 30%.

Tips: When selecting an all steel test bench, ensure it meets your specific testing requirements. Consider opting for benches with built-in safety features like non-slip surfaces and weight distribution systems. Additionally, always check for compatibility with your existing testing equipment to avoid future modifications.

When selecting an all steel test bench, durability is a paramount consideration. Steel, known for its strength and resistance to bending or breaking, offers a robust framework that can withstand the considerable forces typically encountered during testing procedures. A well-constructed steel test bench should include features such as reinforced joints and high-quality welds, ensuring it can endure repetitive use over time. Furthermore, resistance to rust and corrosion is crucial, particularly in humid or chemically charged environments, as this will significantly extend the lifespan of the equipment.

Stability is another critical factor to consider. A test bench should be designed to prevent wobbling or tipping under load, which is essential for maintaining accurate results and ensuring operator safety. Look for benches that offer a solid base and adjustable leveling feet, allowing them to be used effectively in various settings. Additionally, design options can greatly influence usability; benches with modular layouts or customizable surfaces can accommodate different testing needs and adapt to specific projects. By carefully evaluating these aspects—durability, stability, and design—you can choose a test bench that best meets your operational requirements.

When selecting an all steel test bench, assessing your budget and potential return on investment (ROI) is crucial. Start by determining the total costs associated with purchasing and maintaining a test bench. This includes initial acquisition costs, shipping, installation, and any necessary upgrades or accessories that may be needed for optimal performance. Establishing a clear budget will help narrow your choices and prevent overspending on features that may not be essential for your specific applications.

Next, evaluate the ROI by considering how the test bench will impact your operations. Analyze factors such as the efficiency gains, time savings, and overall productivity improvements that an all steel test bench can offer. Visualize the long-term benefits that outweigh the initial investment, such as reduced downtime and enhanced testing accuracy. By calculating the cost savings and performance enhancements over time, you can make a well-informed decision that aligns with your operational goals and financial constraints. Always remember that the right choice should not only fit within your budget but also provide significant value and support your testing needs over the long haul.