When it comes to selecting the appropriate centrifugal fan for your specific requirements, understanding the intricacies of application and performance is paramount. John Smith, a renowned expert in the ventilation industry, emphasizes that "the right centrifugal fan can significantly enhance the efficiency of your system, making it crucial to consider your unique needs before making a purchase." With a plethora of options available, from differing sizes to various motor specifications, the process can be daunting for both novices and seasoned professionals alike.

Centrifugal fans play a vital role in various industrial and commercial applications, providing essential airflow and pressure levels required for optimal operation. However, the effectiveness of a centrifugal fan is not solely determined by its specifications; it also hinges on how well it matches the operational demands of the system it serves. To aid in making informed decisions, it is essential to focus on key factors such as airflow requirements, pressure needs, and energy efficiency. By understanding these critical elements, users can ensure their chosen centrifugal fan not only meets expectations but also contributes to the overall performance of their ventilation systems.

Centrifugal fans are crucial components in various industrial and commercial applications, serving the essential function of moving air or gases efficiently. Understanding the basics of how these fans operate is key to selecting the right one for specific needs.

Centrifugal fans work by drawing air into the center of the fan via an inlet and then pushing it outwards through a discharge outlet. The design of the fan blades and the casing significantly influence airflow and pressure, making it vital to consider the specific requirements of your application, such as pressure needs and volume of air movement.

Different applications call for different types of centrifugal fans. For instance, in HVAC systems, fans are commonly used to circulate air within buildings, ensuring adequate ventilation and maintaining temperature control.

In industrial environments, centrifugal fans are often utilized for exhaust systems, dust collection, or material handling. It is essential to assess factors such as the environment where the fan will operate, whether it needs to handle particulate matter, and the required noise levels. Understanding these applications and their demands can lead to better-informed decisions when choosing the right centrifugal fan, ultimately ensuring optimal performance and longevity.

When selecting a centrifugal fan, it's crucial to consider several key factors that can significantly impact performance and efficiency. Firstly, understanding the specific application requirements is essential. This includes determining the volume flow rate, pressure needs, and the type of material being handled—whether it’s air, dust, or vapors. Analyzing these parameters helps ensure that the fan can effectively meet the demands of your system without excessive energy consumption or premature wear.

Another important aspect to assess is the fan's design and construction materials. The choice of materials affects durability, resistance to corrosion, and overall performance under various operating conditions. Furthermore, consider the fan's noise levels and vibration characteristics, especially if it will be installed in a sensitive environment. A fan designed for low noise operation may be necessary in residential or commercial applications to maintain a comfortable atmosphere. By focusing on these critical factors, you can make a more informed decision that aligns with your specific needs and enhances operational efficiency.

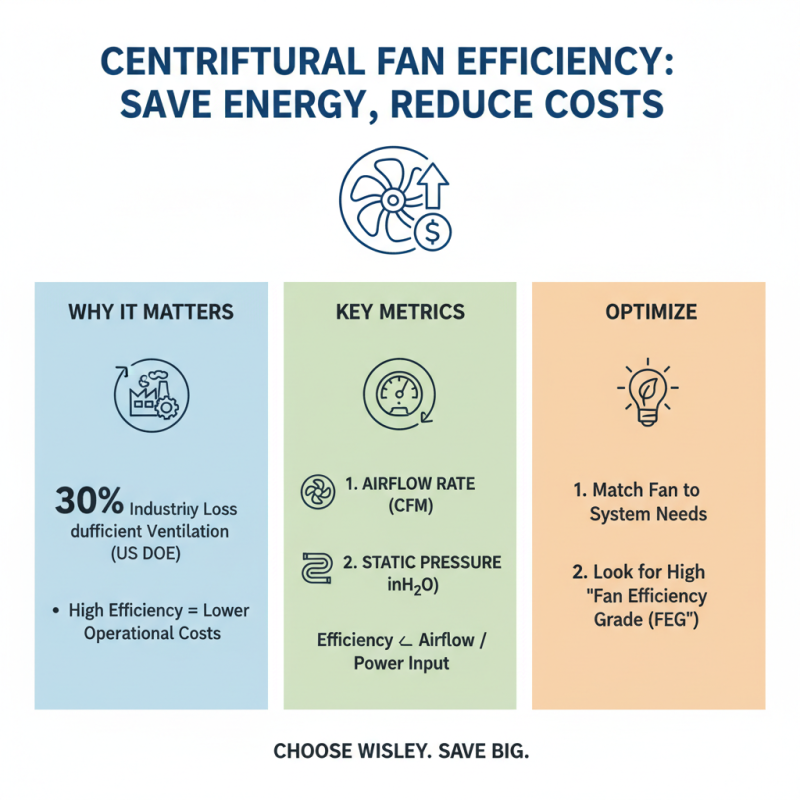

When it comes to selecting the right centrifugal fan for your specific needs, understanding your airflow and pressure requirements is crucial to optimize performance. The interplay between airflow—measured in cubic feet per minute (CFM)—and static pressure is fundamental in determining the efficiency and effectiveness of the fan. According to recent industry studies, achieving the right balance can lead to a 20-30% increase in overall system efficiency. It is essential to assess the specific demands of your application, as insufficient airflow can lead to inadequate cooling or ventilation, while excessive pressure might strain the fan, leading to premature failure.

Tip: Begin by calculating the total airflow requirement of your system based on its design and intended use. For example, HVAC systems typically require a minimum airflow standard of 1 CFM per square foot of floor area for proper air distribution. Remember to also consider factors such as duct length and bends, which can affect pressure drop and overall fan effectiveness.

Additionally, it’s important to factor in the fan's operating environment. High-temperature or corrosive environments require fans constructed from durable materials designed to withstand wear and tear. Research indicates that fans with variable frequency drives (VFDs) can provide better control over airflow and energy consumption, resulting in a significant reduction in operating costs—by as much as 50% in some applications. By thoroughly assessing your airflow and pressure requirements, you can select a centrifugal fan that not only meets your performance needs but also enhances your system's longevity and efficiency.

When selecting the right centrifugal fan for your specific needs, evaluating fan efficiency and energy consumption is critical. A fan's efficiency can significantly affect operational costs, especially in continuous use scenarios. According to the U.S. Department of Energy, energy losses in inefficient ventilation systems can account for up to 30% of total energy consumption in industrial plants. Therefore, understanding the fan’s performance metrics, such as airflow rate and static pressure, is essential for optimizing energy use without compromising on performance.

Additionally, the efficiency rating of a centrifugal fan, typically represented as the Fan Efficiency Grade (FEG), provides valuable insights into energy consumption. An FEG score signifies how effectively the fan converts electrical power into air movement, with higher scores indicating better efficiency. For instance, a fan designed to operate with a high FEG can result in energy savings up to 55% compared to standard designs. The importance of selecting an energy-efficient fan extends beyond immediate utility savings; it also contributes to a facility's overall sustainability goals, reducing the carbon footprint associated with energy consumption.

When selecting a centrifugal fan, one of the most critical aspects to consider is its maintenance needs and expected longevity. Regular maintenance is essential for maximizing the lifespan of your fan and ensuring optimal performance. This includes routine inspections to check for signs of wear, balancing issues, or unusual noises that may indicate mechanical problems. Keeping the fan clean and free of debris is also vital, as accumulation can lead to reduced efficiency and increased energy consumption.

In addition to maintenance, understanding the lifespan of a centrifugal fan is crucial for long-term operational planning. Factors such as the fan's design, materials used, and operating conditions all influence its durability. Selecting a fan built with high-quality components can significantly enhance its longevity, while also considering the environment in which it operates. For instance, fans used in harsh conditions may require more frequent maintenance and could have a shorter lifespan than those in controlled environments. Evaluating these aspects will ensure you choose a fan that not only meets your immediate needs but also remains reliable and efficient over the long run.