The Spray Tower is an essential component in various industrial applications, designed to enhance efficiency and effectiveness in processes such as air pollution control, chemical manufacturing, and wastewater treatment. By utilizing a sophisticated mechanism that involves the spraying of liquids in a controlled manner, Spray Towers facilitate optimal contact between liquids and gases, leading to improved mass transfer and separation. This introduction aims to elucidate the core principles of Spray Towers while exploring their operational mechanisms and diverse applications across multiple industries.

In essence, a Spray Tower operates by channeling gases through a vertical cylinder where liquid droplets are introduced, allowing for the interaction of the two phases. This interaction not only aids in the removal of contaminants from industrial exhaust but also plays a significant role in crucial processes such as absorption and reaction. As industries continue to prioritize sustainability and environmental compliance, understanding the functionality of Spray Towers becomes increasingly important. This article will delve deeper into the working principles of Spray Towers, highlighting their pivotal role in modern industrial practices and their contribution to enhanced operational outcomes.

A spray tower is a key component in various industrial applications, primarily used for pollution control and gas absorption processes. It consists of a vertical cylindrical structure where a liquid is sprayed or injected into a gas stream. As the two phases interact, the liquid droplets help to remove contaminants from the gas or facilitate chemical reactions. This technology is essential in sectors such as chemical manufacturing, waste treatment, and power generation, where controlling emissions is crucial for environmental compliance.

The operation of a spray tower relies on the principle of mass transfer between the gas and the liquid. As the gas rises through the tower, it encounters a fine mist of liquid sprayed from the top. The design and operational parameters, such as droplet size and flow rate, significantly influence the efficiency of contaminant removal. By maximizing surface area contact between the droplets and the gas, spray towers can effectively reduce particulate matter, volatile organic compounds, and other hazardous emissions, making them an integral part of modern industrial processes.

| Dimension | Description |

|---|---|

| Height | Typically ranges from 10 to 30 meters, depending on the application. |

| Diameter | Common diameters range from 1 to 5 meters. |

| Flow Rate | Flow rates can vary from 10 m³/h to over 1000 m³/h based on the design. |

| Receiving Fluid | Water or chemical solutions for various scrubbing applications. |

| Applications | Used in air pollution control, cooling systems, and wastewater treatment. |

| Efficiency | Can achieve over 95% removal efficiency for certain pollutants. |

| Maintenance | Regular inspections and cleaning to prevent blockages and ensure efficiency. |

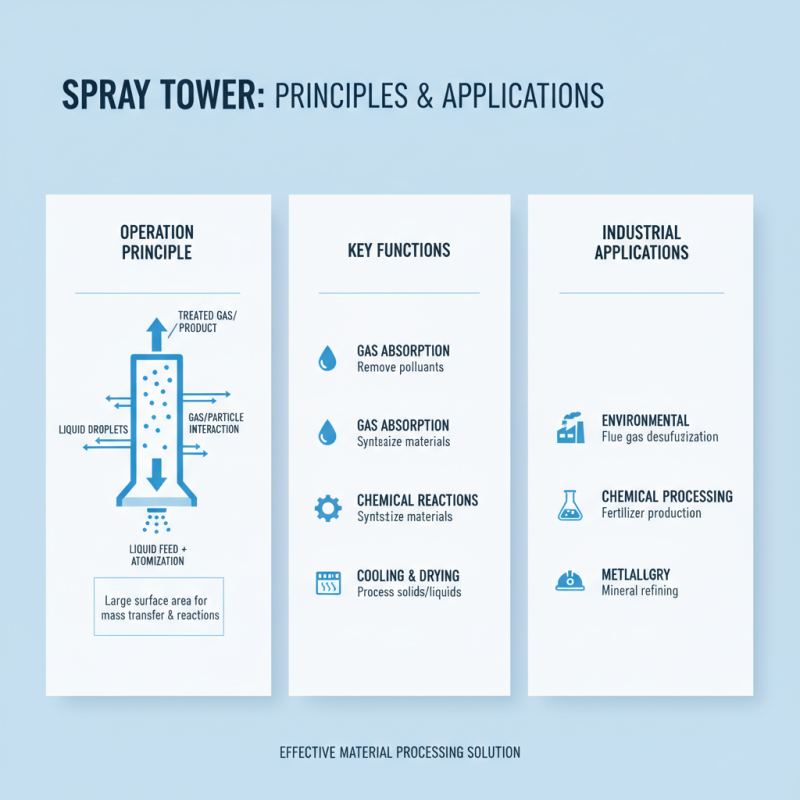

Spray towers are critical components in various industrial applications, leveraging their unique principle of operation for effective material processing. The fundamental idea behind a spray tower involves creating a controlled environment where liquid droplets are formed and interacted with gases or solid particles. The process typically starts with a liquid feed being atomized into fine droplets through nozzles or spray heads, which then ascend in a vertical column. This configuration promotes a large surface area for effective contact, allowing for efficient mass transfer and chemical reactions to occur.

As droplets travel upwards in the tower, they encounter rising gas streams, which can be either air or other gases. This interaction facilitates heat and mass transfer between the liquid and gas phases, enabling purposes such as absorption, cooling, or drying. The design of the spray tower, including factors like droplet size and gas flow rate, is crucial in maximizing efficiency. By adjusting these parameters, industries can optimize the tower's performance for specific applications, from removing contaminants in air pollution control to producing high-purity chemicals in manufacturing processes.

Spray towers are versatile devices widely used across various industrial applications. In the chemical industry, for instance, they are essential in processes such as gas scrubbing and waste treatment. By introducing liquid in fine droplets into a gas stream, spray towers facilitate efficient mass transfer between the phases, enabling the removal of pollutants and undesirable compounds from emissions. This process not only helps in meeting environmental regulations but also enhances the quality of the air released into the atmosphere.

In the food and beverage industry, spray towers play a crucial role in processes like flavoring and drying. By utilizing atomization techniques, manufacturers can uniformly coat products with flavors or preservatives, ensuring consistency in taste and shelf life. Additionally, spray drying is a popular method for creating powdered products, where the liquid feed solution is transformed into a dry powder through rapid evaporation, preserving the product's integrity and nutritional value. As such, spray towers serve as indispensable tools for ensuring efficiency and quality across various industrial sectors.

Spray towers are essential components in many industrial processes, particularly for controlling emissions from exhaust gases. These systems work by introducing a liquid—often water or a chemical solution—into a vertical column where it interacts with the gas stream. As the gas passes through the tower, the droplets formed from the liquid absorb or react with contaminants, effectively removing harmful substances from the emissions. According to the U.S. Environmental Protection Agency (EPA), spray towers can achieve up to 90% removal efficiency for certain pollutants, making them a vital tool for industries striving to meet stringent environmental regulations.

The benefits of using spray towers extend beyond mere compliance with emission standards. They provide a cost-effective solution for controlling volatile organic compounds (VOCs) and particulate matter, which are significant contributors to air pollution. A report by the International Journal of Environmental Engineering indicates that industries employing spray towers can reduce their overall emissions by 45% on average, leading to lower operational costs associated with fines and health-related expenses. Additionally, these systems can be integrated with existing machinery with relative ease, minimizing the need for extensive modifications and enabling a smoother transition toward greener operations.

The maintenance and optimization of spray towers are crucial to ensuring their efficiency and longevity in industrial applications. Regular maintenance includes inspecting the spray nozzles for wear and clogging, as these factors can significantly impact the performance of the tower. Routine checks of the system's pumps and valves are also essential to maintain proper pressure and flow rates. Cleaning and replacing components as necessary not only minimizes downtime but also enhances operational efficiency, leading to better overall performance and lower maintenance costs.

Optimization of spray towers involves fine-tuning operating parameters such as liquid and gas flow rates, temperature, and pressure. By analyzing operational data, facility managers can adjust these parameters to maximize mass transfer efficiency and reduce energy consumption. Implementing advanced control systems can facilitate real-time monitoring and automatic adjustments based on operational conditions. Furthermore, integrating predictive maintenance strategies can prevent unexpected failures and ensure the system operates at peak performance. By focusing on both maintenance and optimization, industries can achieve effective and sustainable operations with their spray towers.